High temperature jet dyeing machine

Product Advantages

1. The liquor ratio is as low as 1:5

2. Wide range of applications

BANANA is suitable for various common gsm fabrics like polyester, polyamide, spandex, cotton, polyester filament, spun, twisting, micro fiber, synthetic fiber and fiber blends.

1) Its overflow nozzle is used for knit fabric dyeing with low head and large flow pump.

2) Could change nozzle diameter based on different fabric, nozzle gap is adjustable.

3. Automatic filtering system (option)

The automatic filtering system is of patent design. It can remove the fluffs automatically for labor saving and short dyeing process.

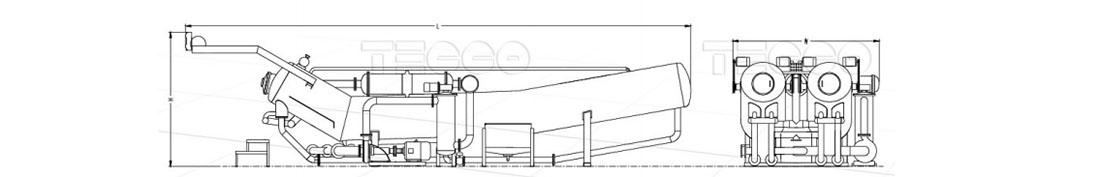

Banana dyeing machine

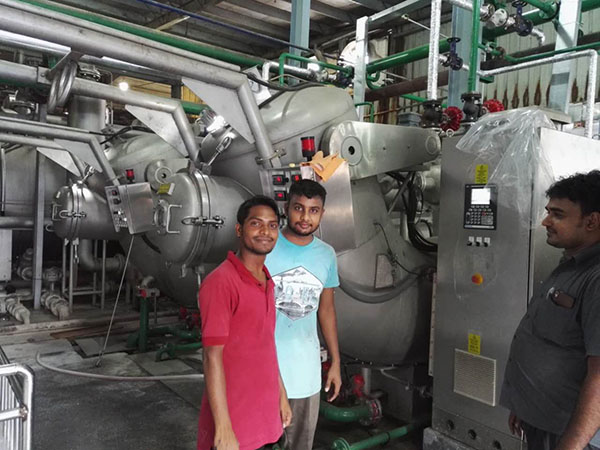

Dyeing site

Extra Large Capacity

Max capacity of single chamber double tube reaches 500kg; Max capacity of the dyeing machine: 2000kg

| Water Consumption | Approx.30 ton/ton fabric (dark color) |

| Power Consumption | Approx. 160 ton/ton fabric |

| Steam Consumption | Approx. 1.6 ton/ton fabric |

| Auxiliaries Consumption | 40% can be saved |

Eco-friendly and Energy Saving dyeing

knitting fabric dyeing

Smart control

Advanced automatic control system;

Flow meter for water supply control;

Intelligent rinsing system;

Proportional heating and cooling system; and quantitative dosing system;

Fabric running speed detecting device;

knit dyeing machine

knit dyeing

BANANA-S

Due to the variety of fabrics, our company has developed BANANA-S single tube series based on the original BANANA machine. It’s mainly suitable for light gsm woven fabric, knit fabric, warp knitting and weft knitting fabric.

Overflow dyeing machine

Professional fabric dye

Product Advantages

1. The liquor ratio is as low as 1:5

2. Max capacity of single chamber single tube reaches 300kg;

3. Max capacity for the dyeing machine: 1200kg

| Water Consumption | Approx.30 ton/ton fabric (dark color) |

| Power Consumption | Approx. 160 ton/ton fabric |

| Steam Consumption | Approx. 1.6 ton/ton fabric |

| Auxiliaries Consumption | 40% can be saved |

Advanced automatic control system

Single tube dyeing machine

Single tube fabric dyeing

Model

| Model Banana type | No. of tubes/chambers | Capacity kg | Total power (kw) | Dimensions (L*W*H)mm | ||

| QD3-S-1T | 1/2 | 300 | 38 | 10300 | 2600 | 3100 |

| QD3-S-2T | 2/4 | 600 | 60 | 10300 | 4100 | 3150 |

| QD3-1T | 1/2 | 500 | 38 | 11500 | 2600 | 3100 |

| QD3-2T | 2/4 | 1000 | 60 | 11500 | 4100 | 3150 |

| QD3-4T | 4/8 | 2000 | 101 | 11500 | 7400 | 3150 |

| Model Banana-S type | No. of tubes/chambers | Capacity kg | Total power (kw) | Dimensions (L*W*H)mm | ||

| QD-S-30 | 1/1 | 30 | 11 | 5900 | 1700 | 2300 |

| QD-S-60 | 1/1 | 60 | 15 | 7500 | 1700 | 2600 |

| QD-150 | 1/1 | 150 | 17 | 7700 | 1850 | 2600 |

| QD-1T | 1/1 | 250 | 21 | 11100 | 2900 | 2800 |

| QD-2T | 2/2 | 500 | 38 | 11100 | 2900 | 2800 |

| QD-4T | 4/4 | 1000 | 60 | 11100 | 5200 | 3000 |

Soft flow jet dyeing machine

Winch dyeing machine process

Video

Fabric dyieng process