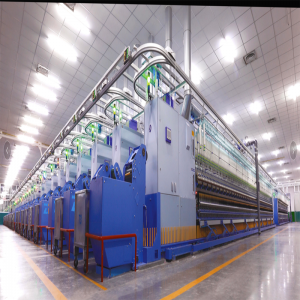

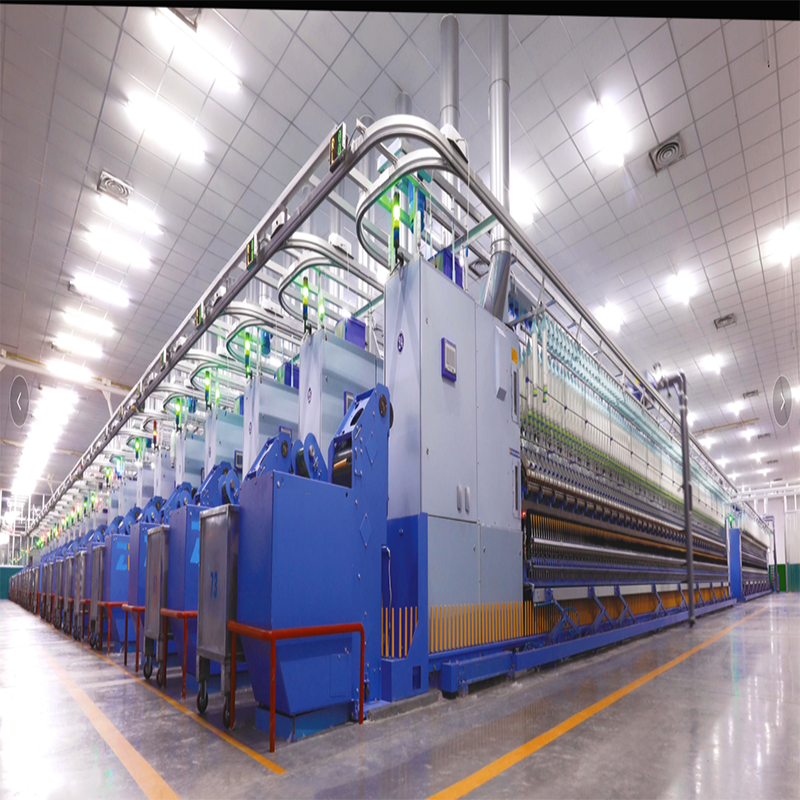

spinning frame function transformation

Automatic collective doffing device

Product Features

The automatic collective doffing device solves the problem of automatic doffing, automatic managing and automatic full tube conveying in spinning process. Reduce labor, reduce labor intensity, improve the degree of spinning automation, improve labor productivity, reduce product costs.

Product Advantage

Doffing indicators: doffing time for 3 minutes, managing time for 25 minutes, intubation rate 98%, Decannulation rate 98%, rate of yarn reserve≥98%.

Investment return: to spin 6-12s yarn for example, after installing collective doffer device,it only takes 2 years to pay for itself.

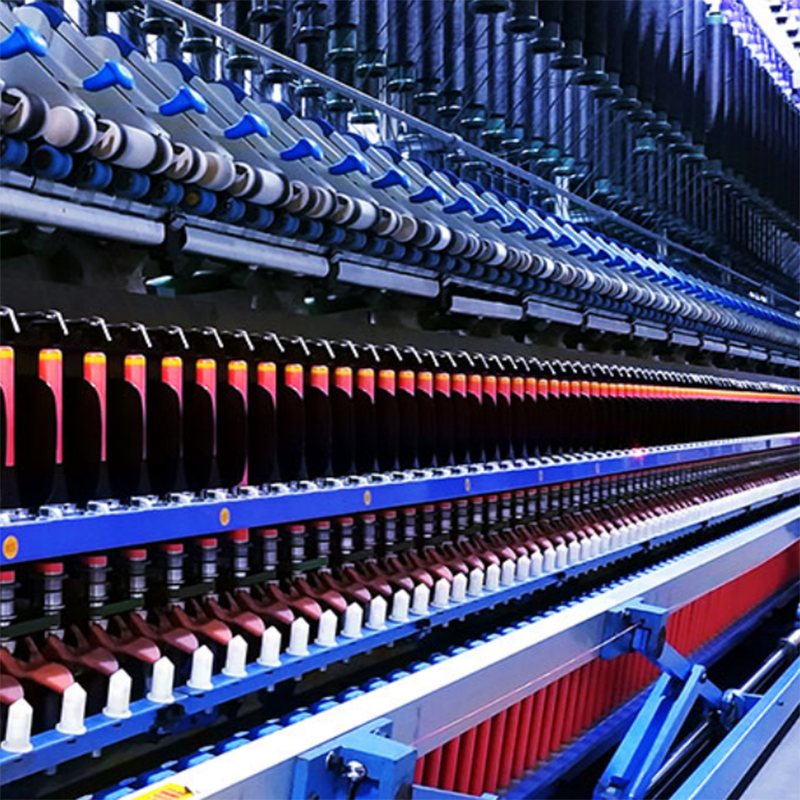

Core-spun yarn/double core-spun yarn device

Core-spun yarn and double core-spun yarn device are compatible with all ring spinning frames. The double filament adopts the form of active feeding.

Scope of application: S-60s spandex elastic core-spun yarn for cotton, hemp, chemical fiber, etc., and cotton core-spun T400+ spandex double core-spun yarn, yarn count range 6s-30s; Can also be spun with less elastic synthetic fibers.

The spandex core-spun yarn and filament core-spun yarn each have a servo drive, so that the two core-spun yarn feeding synchronously, to ensure the same feeding ratio.

The draft ratio of spandex can be adjusted from 1.3 to 5 times, and the draft ratio of filament can be adjusted from 1 to 2 times. Core-spinning process is input through color touch screen.

The spandex wire guide rod is made of cold-drawn seamless composite pipe, and the filament wire guide roller is made of seamless steel pipe by fine grinding. The surface is specially treated and the draft ratio is stable, which ensures the yarn quality.

The spinning wheel is flexible and stable, and the yarn quality is good. The position of the guide wheel can be moved horizontally by adjusting the knob; The height of the guide wire wheel is adjustable, and the feeding Angle of the core wire is adjusted, which can meet the requirements of various core-wrapped yarn varieties and make it in an ideal process state.

Guide rod, guide wheel are black, black and white, easy to observe and operate, effectively prevent hollow yarn.

Slub yarn device

Product Features

Slub yarn section/color yarn device can be installed on warp and weft spinning machines F1520, F1516, FA506, FA502 and so on.

Shanghai No.2 Spinning Machine.EJM138LD(long car), EJM128K, FA503, FA507;Germany ZINSER 319SL, ZINSER 360,ZINSER R71; Germany RIETER G32, K44 and other spinning frame.

Slub yarn device can spin regular slub yarn, irregular slub yarn, slub with slub, fuzzy proportion, multi-level fuzzy, random value etc.slub yarn. The length of the slub is above 25mm, the distance between the slub is above 30mm, the thickness of the slub is 50-600%

Product Advantage

Lean technology, high precision, industry-winning full machine dynamic random tracking technology

It adopts the PLC bus control system, and the response speed reaches 1ms, which ensures the stable quality of slub yarn when the vehicle is on or off or the speed fluctuates. It is especially suitable for the main motor frequency conversion speed regulation.

Excellent color touch screen man-machine interface, can carry on the process input, edit, and display, simple and intuitive operation.

Power failure protection function: the function of continuous slub yarn head when sudden power failure is optional when ordering.

Performance and advantages: reliable performance, easy to use.

Send experienced engineer to undertake slub yarn craft training, Package education package

Section color yarn device

Product Features

Section color yarn is widely used in clothing fabrics by virtue of its own yarn diversity and three-dimensional sense and rich color changes.

Section color yarn is roving with more than two kinds of raw materials (colors),A continuous feeding of roving as main body is realized by adding a section of color yarn device on the spinning frame. Another kind of roving is the intermittent feeding of the auxiliary yarn, and the formation of a single yarn with a section of color, color point, slub.During production, one motor drives the middle roller and the rear roller separately: continuous feeding of the middle roller and intermittent feeding of the rear roller.

Product Advantage

Lean technology, high precision, industry-winning full machine dynamic random tracking technology

It adopts the PLC bus control system, and the response speed reaches 1ms, which ensures the stable quality of slub yarn when the vehicle is on or off or the speed fluctuates. It is especially suitable for the main motor frequency conversion speed regulation.

Excellent color touch screen man-machine interface, can carry on the process input, edit, and display, simple and intuitive operation.

Power failure protection function: the function of continuous slub yarn head when sudden power failure is optional when ordering.

Performance and advantages: reliable performance, easy to use.

Send experienced engineer to undertake slub yarn craft training, Package education package

Super flexible device

Product Features

With the improvement of people's requirements for garment fabrics and knitted fabrics, fabric market products gradually diversify;In recent years, super flexible yarn has been widely used in sports and leisure clothing for its excellent softness, air permeability, moisture absorption and sweat conduction. According to the market trend, super flexible yarn is applied to low torque super flexible elastic denim fabric, and a kind of low torque elastic super flexible denim fabric is developed, which is characterized by both the soft and comfortable feel of super soft cotton elastic fabric and the advantages of high elastic molding, moisture absorption and sweat, air permeability and dry. Made of Jeans clothing, can give the wearer to bring multiple comfort.

Product Advantage

When spinning super flexible yarn, on the basis of the original spinning, reduce 10% twist, strength can keep the original data, improve strength CV%, hair improve about 30%, yarn softness is more obvious, spindle speed unchanged, output increased 10%!

On the basis of the original spinning, reducing the twist by 20%-25% will decrease the strength by about 10% (the strength can be improved by improving the raw cotton grade, and the strength of the original yarn remains unchanged), reduce the spindle speed by 10%, and increase the output by 10%.

All of these can increase production by 10%, with a return on investment period of 3 months, and add new yarn varieties!

Can spin slub super flexible yarn, core super flexible yarn, flat super flexible yarn, siro compact super flexible yarn and so on! Very widely used!

Variation-count and variation-twisted slub yarn device

Product Features

In order to meet the needs of the market, Our company intelligent development the variable twist device.

It can change the speed of three rollers at the same time, the front roller and middle and rear rollers are respectively driven by two servo motors, which can produce different front roller speed and middle and rear roller speed according to different processes. This device has all the functions of the original slub yarn device, and can spin super long and large multiple slub and Ultrashort slub..

Product Advantage

In the drive system of the original spinning frame,he middle and rear rollers and the front rollers are disconnected first, add two servo motors are installed respectively.

A servo motor drives the middle and rear rollers, another servo motor drives the front roller. The encoder is installed at the main shaft of the machine head.

Control cabinet (PLC control system) is installed on the upper part of the machine head, and reasonable design of fuzzy number, twist, length, thickness and density of slub and other technical parameters.

The variation-count and variation-twisted slub yarn device is used to make the base yarn and the slub yarn get different twist in the spinning process, and the base yarn gets larger twist and the slub yarn gets smaller twist, thus realizing the rationalization and diversification of twist between the base yarn and the slub yarn in the same yarn.

Electronic bobbin formation system

Product Features

The system can realize computer network control, real-time monitoring of spinning frame working state, real-time statistics of output, process parameters and other management data, automatic production report and analysis, convenient management. And can be connected with mobile phone APP software, convenient production workers to deal with the fault and management personnel real-time monitoring.

Product Advantage

The electronic lifting system of QD200 adopts servo-controlled steel collar plate, which has uniform running smoothness,the capacity of the tube yarn is greatly increased while the short working distance is reduced,and it's not going to come out of the loop.Through servo control program speed up and down, effectively improve the phenomenon of broken head during driving.Parameters can be set arbitrarily, really achieve energy saving, labor saving, cost saving.

QD200 electronic CAM can be matched with all specifications of the spinning frame,Electronic CAM can also replace the original mechanical CAM transformation of the old machine.

Cotton spinning on-line single spindle testing

Product Features

The application of single spindle on-line monitoring roving automatic stop system in spinning frame can promote several projects directly related to spinning production management and cost, It is not only an effective auxiliary tool to improve spinning production management and management efficiency, but also an important platform for networked intelligent connection and labor reduction in future spinning.

Product Advantage

By installing a photoelectric sensor on the steel collar plate, the signal is detected when the wire ring is rotating, and the speed information of the wire ring is obtained, which can distinguish whether the yarn is broken. If the yarn is broken, the roving stop feeding device is controlled to break the roving within 2 seconds. In this way, the quick inspection can be completed instead of manual work, and the spun roving with broken ends can be pulled off quickly

Full CNC head-stock transformation

Product Features

The whole CNC head-stock is the front, middle and rear rollers, the steel collar plate lifting with a servo direct drive, the main motor with frequency converter drive, modify the process as long as the touch screen setting modification can, no longer need to replace the gear. It is an intelligent spinning system integrating slub yarn, colored yarn, variable count and variable twist and electronic lifting. All process changes are operated on the display screen without changing any process gear. Simple and convenient operation, high efficiency and energy saving.

Product Advantage

The system can realize computer network control, real-time monitoring of spinning machine working status, real-time statistics of output, process parameters and other management data, automatically generate production reports and analysis, convenient for enterprise management, and can be connected with mobile phone APP software, convenient for production workers to deal with faults and management personnel real-time monitoring