The winch dyeing machine is one of the most commonly used machines in textile manufacturing. They are used to dye a variety of fabrics such as cotton, silk, and synthetics. A winch dyeing machine is a batch dyeing system that uses a winch to move the fabric throughout the dyeing process. In this blog we will discuss how a winch dyeing machine works.

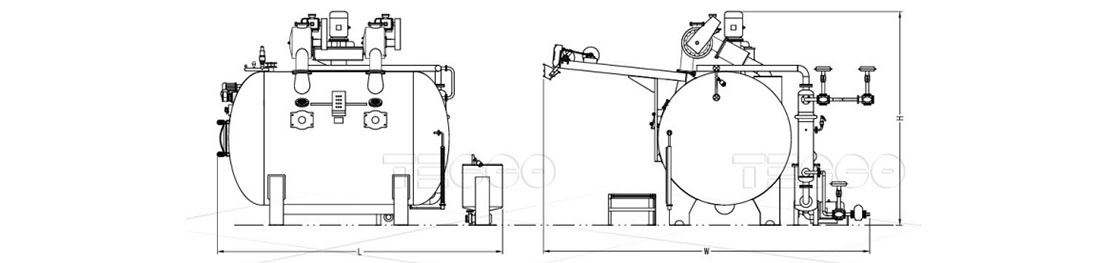

The winch dyeing machine consists of a large stainless steel container, a winch and several nozzles. Fill the container with water and adjust the temperature and pH accordingly. The fabric is then loaded into the machine and the winch is started. The fabric is circulated in the container by a winch, and the nozzles distribute the dye evenly throughout the fabric.

The working principle of the winch dyeing machine is based on the principles of heat transfer, mass transfer and diffusion. The fabric is first wetted in a container, and then the dye is added. The temperature and pH of the vessel are controlled to ensure the dyeing process is effective. A winch then circulates the fabric through the container, and nozzles distribute the dye evenly.

Winch dyeing machines have several advantages over other dyeing systems. It is a batch system, which means it can process a large number of fabrics at one time. It is also very efficient as it dyes fabrics quickly and evenly. Capstan dyeing machine can also be used for many kinds of fabrics, it is a multifunctional machine for textile industry.

Another advantage of the winch dyeing machine is that it is environmentally friendly. The machine uses less water, energy and dyes than other dyeing systems. It also produces less waste, which makes it a sustainable option for textile manufacturers.

In conclusion, the winch dyeing machine is an important part of the textile industry. It is an efficient and versatile machine that can handle a wide variety of fabrics. The working principle of the winch dyeing machine is based on the principles of mass transfer, heat transfer and diffusion. By using this machine, textile manufacturers can save time and resources while producing high-quality fabrics.

Post time: May-29-2023