Dyeing Apparatus Fabric Polyester Nylon Cotton Dyeing Machine

Range of application

This machine is a double function machine which can be used for small bath ratio dyeing and ordinary internal and external dyeing. Can do air cushion type or full - flush type.

Suitable for dyeing: various kinds of polyester, polyamide, fine wheel, cotton, wool, linen and various blended fabrics for dyeing, cooking, bleaching, cleaning, and other processes.

Also suitable for lace, zipper and zipper belt, elastic for dyeing, cooking, bleaching, cleaning, and other processes.

Equipped with pipeline type water pump, with X plate positive and negative circulation commutator, supporting small bath ratio dyeing.

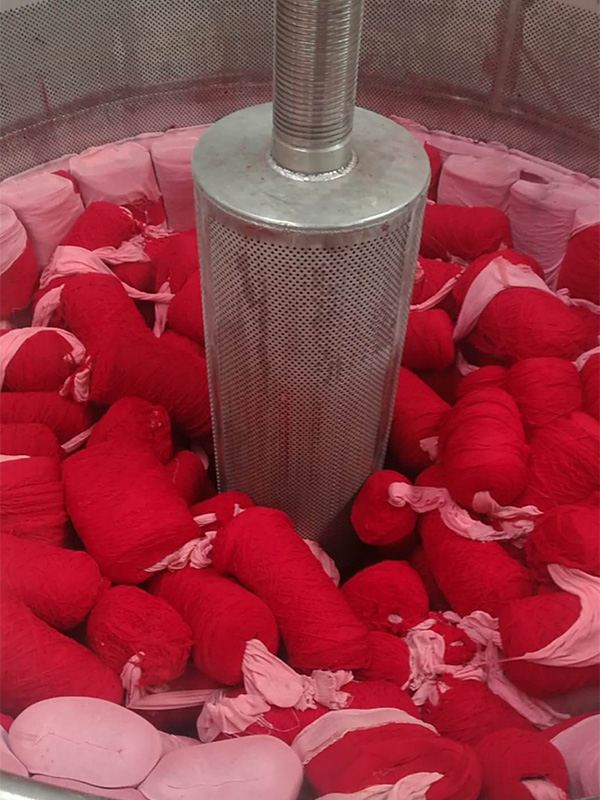

Bread type nylong dyeing

Dyeing site

Nylon yarn carrier

Dyeing tank

Machine structure

1. One set of main cylinder block.

2. One set of yarn frame.

3. One electric cabinet.

Equipped with HG310A Chinese and English microcomputer, stainless steel control box. Inverter (motor over 22kw with inverter), self-developed full function PLC. AIRTAC solenoid valve.

Due to the high humidity and temperature in the working environment of the converter on the dyeing machine, the electrical components are easy to be damaged, which requires the support of after-sales service. The frequency converter equipped by our company is a special frequency converter for dyeing machine, which has been specially designed for dustproof and moisture-proof. The warranty period is 18 months. However, due to the different requirements of the customer, the inverter can be provided by the customer, the base price can be deducted from the price of dyeing machine inverter. All the control functions of the dyeing machine are in the PLC independently developed by our company. PLC is combined with HUAGAO 310A computer to realize fully automatic control. And PLC is open, some customers' special control requirements can also be written into the PLC.

4. Complete valve (single inlet and single drainage).

Valves below Dg50 are stainless steel pneumatic rectangular valves, and valves above Dg50 are stainless steel pneumatic ball valves.

5. Main pump and connection pipeline. (Internal connection pipeline).

Automatic feeding device

The dye can be added into the main cylinder automatically after the chemical barrel is evenly internalized, reducing labor intensity and improving work efficiency. And can be flexible feeding. Cotton dyeing and other yarns need to be fed many times, need to be equipped with automatic feeding device. The combination of the pressure sensor and PLC can realize the full automatic control of the water level of the barrel.

1. Feeding barrel body.

2. Feed pump.

3. Stirring motor.(non-stirring motor below QXB60, recoil mixing function of dye stirring feeder pump stirring).

4. Complete the valves (7) and connection pipes.

We have equipped the automatic material system for this batch of dyeing machines over 200kg.

Model and capacity

Model and capacity for different yarn dyeing

|

Model |

Capacity of cone (based on 1kg/cone) Center distance of yarn rod O/D165×H165 mm |

Capacity of polyester high elastic bread yarn |

Capacity of nylon high elastic bread yarn |

Main pump power |

|

QD-20 |

1 pipe*2layer=2 cones |

1kg |

1.2kg |

0.75kw |

|

QD-20 |

1 pipe*4layer=4 cones |

1.44kg |

1.8kg |

1.5kw |

|

QD-25 |

1 pipe*5layer=5 cones |

3kg |

4kg |

2.2kw |

|

QD-40 |

3 pipe*4layer=12 cones |

9.72kg |

12.15kg |

3kw |

|

QD-45 |

4 pipe*5layer=20 cones |

13.2kg |

16.5kg |

4kw |

|

QD-50 |

5 pipe*7layer=35 cones |

20kg |

25kg |

5.5kw |

|

QD-60 |

7 pipe*7layer=49 cones |

30kg |

36.5kg |

7.5kw |

|

QD-75 |

12 pipe*7layer=84 cones |

42.8kg |

53.5kg |

11kw |

|

QD-90 |

19 pipe*7layer=133 cones |

61.6kg |

77.3kg |

15kw |

|

QD-105 |

28 pipe*7layer=196 cones |

86.5kg |

108.1kg |

22kw |

|

QD-120 |

37 pipe*7layer=259 cones |

121.1kg |

154.4kg |

22kw |

|

QD-120 |

54 pipe*7layer=378 cones |

171.2kg |

214.1kg |

37kw |

|

QD-140 |

54 pipe*10layer=540 cones |

240kg |

300kg |

45kw |

|

QD-152 |

61 pipe*10layer=610 cones |

290kg |

361.6kg |

55kw |

|

QD-170 |

77 pipe*10layer=770 cones |

340.2kg |

425.4kg |

75kw |

|

QD-186 |

92 pipe*10layer=920 cones |

417.5kg |

522.0kg |

90kw |

|

QD-200 |

108 pipe*12layer=1296 cones |

609.2kg |

761.6kg |

110kw |

Video

Dyeing site

Nylon cone carrier

Nylon yarn dewater