OEM/ODM Factory Yarn Dyeing Machine Working Principle - Jig dyeing machine hthp front open – Singularity

OEM/ODM Factory Yarn Dyeing Machine Working Principle - Jig dyeing machine hthp front open – Singularity Detail:

Main technical parameter

| Rolling diameter | Φ1200mm |

| Roller width | 3800mm |

| Efficient width | 3600mm |

| Fabric speed | 0~130m/min |

| Tension range | 0~65kg |

| Motor power | 2 sets 15kw |

| Temperature control range | 0-130℃ |

| Diameter or cloth roller | Φ300mm |

| Shape size | 5800mm(L)*3100 mm(W)*2700mm(H) |

Main control functions

1. Whole machine is dual frequency converter control system, human-computer operation interface.

2. Set of constant tension, constant linear speed.

3. Functions of manual, automatic, speed up, slow down.

4. Automatic head back, automatic record the lines, automatic stop machine, automatic swing function if line is full.

5. Whole machine automatic temperature control, technological operation.

6. Operation screen programmable set, technology storage, automatic identification, automatic alarm.

Electric appliance and machine layout

| 1 | Controller | Japan Omron PLC |

| 2 | Frequency converter | 2 sets of Yaskawa frequency converter are 15KW |

| 3 | Operation interface | 10 inches Weinview Colorful touch screen(Taiwan) |

| 4 | Motor | 2 sets of 15kw linking type motor reducing gear |

| 5 | Low-voltage electrical components | Schneider |

| 6 | Encoder | AKS |

| 7 | Solenoid valve | AIRTAC pneumatic solenoid valve |

| 8 | High temperature vat body | Vat body is made of Q235-B, designed pressure 0.35Mpa, designed temperature: 140℃, there is pressure vessel license |

| 9 | Main cloth roller | Dia. 325mm, coated with SUS304 of 2mm thick |

| 10 | Bottom cloth guide roller | Dia. φ150mm, SUS304 roller |

| 11 | Upper cloth guide roller | Dia. φ125mm, SUS304 roller |

| 12 | Dye vessel | Made of 2.5mm SUS304 |

| 13 | Tension frame | Made of SUS304 |

| 14 | Electrical cabinet | Made of stainless steel |

| 15 | Machine frame | One set of machine frame |

| 16 | Seal of main rollers | Two ends of main roller adopt mechanical seal, seals are from Wuxi Huifeng Company |

| 17 | Valve | Air inlet is stainless steel pneumatic Y-valve, drainage valve is manual stainless steel ball valve, from Wuxi Dongyu factory |

| 18 | Heating system | Indirectly and directly heating dye liquor, SUS304 tube |

| 19 | Fabric outlet | Winding outlet device |

Video

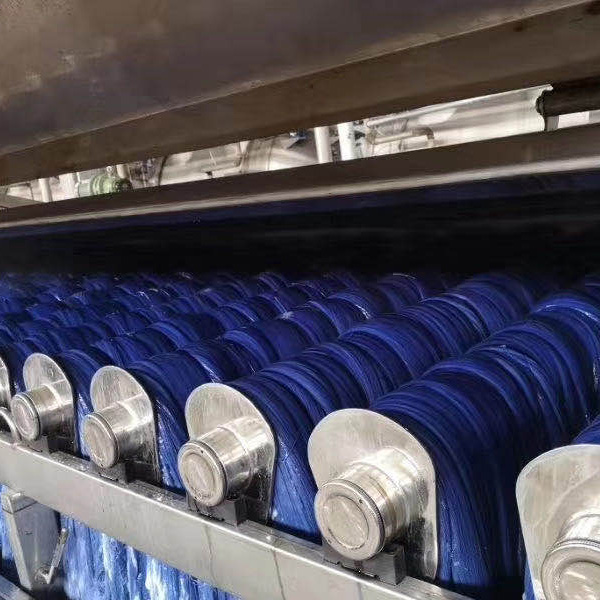

Jig dyeing process

Product detail pictures:

Related Product Guide:

Our primary goal is to offer our clients a serious and responsible business relationship, providing personalized attention to all of them for OEM/ODM Factory Yarn Dyeing Machine Working Principle - Jig dyeing machine hthp front open – Singularity , The product will supply to all over the world, such as: Amsterdam, Uzbekistan, Palestine, We have more than 10 years experience of production and export business. We always develop and design kinds of novel products to meet the market demand and help the guests continuously by updating our products. We are specialized manufacturer and exporter in China. Wherever you are, please join us, and together we will shape a bright future in your business field!

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!

Write your message here and send it to us