Factory directly Dyeing Process Of Cotton Fabric - Double variable frequency Jig dyeing machine at room temperature and pressure – Singularity

Factory directly Dyeing Process Of Cotton Fabric - Double variable frequency Jig dyeing machine at room temperature and pressure – Singularity Detail:

Application

This roll dyeing machine is suitable for viscose, nylon, silk, cotton, hemp and blended fabrics.

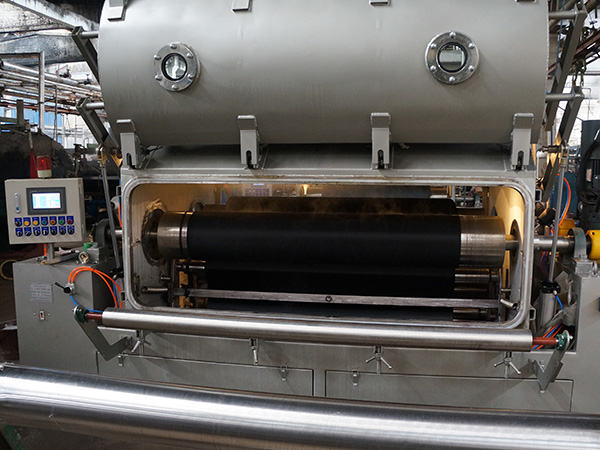

Cotton fabric jig dyeing machine

Middle temperature jig dyeing machine

Technical details

|

1 |

Roll diameter |

φ900mm |

|

2 |

Width of roller |

2000mm |

|

3 |

Working width |

1800mm |

|

4 |

Speed of fabric |

0-130m/min |

|

5 |

Tension range |

0-60kg |

|

6 |

Power of motor |

5.5kw*2 |

|

7 |

Range of temperature control |

0-105℃ |

|

8 |

Diameter of fabric roll |

Φ275mm |

|

9 |

Overall size |

3700mm(Length)*1900mm(width)*2100mm(Height) |

Nylon fabric dyeing machine

User of jig dyeing machine

Control function sheet

1. The machine is double frequency conversion electrical control system, hd color touch screen, man-machine interface.

2. Achieve constant tension, constant line speed setting.

3. With automatic measure of thickness, automatic turn, automatic track number, automatic stop, automatic road full control and other functions.

4. Operation screen programmable setting, process storage, automatic identification, automatic alarm.

5. Five sampling points can be located.

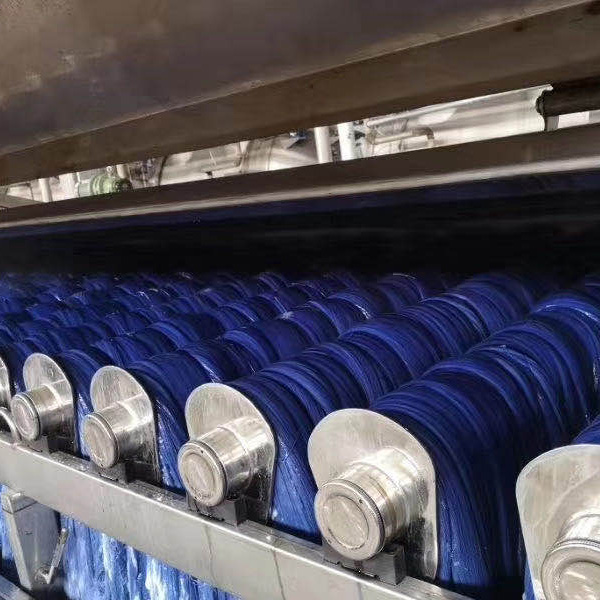

Dyeing tank

Silk jig dying machine

Production requirements and configuration table

| 1 | Controller | OMRON PLC JAPAN |

| 2 | Inverter | Two 5.5kW YASKAWA vector transducers |

| 3 | Operate interface | 7 inch KUNLUN TONGTAI HD color touch screen |

| 4 | Motor reducer | Two 5.5kW vertical connected motor reducers |

| 5 | Low-voltage electrical component | DELIXI |

| 6 | Mean fabric roller | Diameter φ275mm, 2mmSUS316L stainless steel coated roller |

| 7 | Type of heating | The dye is heated directly and indirectly, SUS304 stainless steel tube |

| 8 | Bottom cloth guide roller | Diameter φ125mm, SUS304 stainless steel roller |

| 9 | Up cloth guide roller | Diameter φ100mm, SUS304 stainless steel roller |

| 10 | Dyeing tank | 2mmSUS304 stainless steel |

| 11 | Tension frame | 3mmSUS304 stainless steel |

| 12 | Electrical cabinet | Stainless steel electrical operating box |

| 13 | Valve | Stainless steel pneumatic Y valve, automatic control |

| 14 | Machine frame | The whole frame adopts SUS201 stainless steel international channel steel, steel plate welding structure |

| 15 | Temperature probe | Equipped with high precision PT100 temperature measuring resistor, WZP-221 |

| 16 | Method of output | Rolling type |

Product detail pictures:

Related Product Guide:

Our rewards are reduce selling prices,dynamic revenue team,specialized QC,sturdy factories,superior quality services for Factory directly Dyeing Process Of Cotton Fabric - Double variable frequency Jig dyeing machine at room temperature and pressure – Singularity , The product will supply to all over the world, such as: Morocco, Kuwait, Chile, Our products are mainly exported to Europe, Africa, America, the Middle East and Southeast Asia and other countries and regions. We have enjoyed a great reputation among our customers for quality products and good services.We would make friends with businessmen from at home and abroad, following the purpose of "Quality First, Reputation First, the Best Services."

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.