China Factory for Dip Dyeing Process - Electricity Built-in HTHP cone yarn dyeing machine – Singularity

China Factory for Dip Dyeing Process - Electricity Built-in HTHP cone yarn dyeing machine – Singularity Detail:

Configuration

1. Computer: LCD computer(China made)

2. Magnetic valve: Taiwan made

3. Electric component: Main components(Siemens)

4. Main pump motor: China made

5. Pump: Mixed-flow pump

6. Electrical cabinet: Stainless steel

7. Safety system: Safety interlocking structure, safety valve equipped on main pump

8. Temperature control: Controlled by computer

9. Circulating system: Manually or automatically control

10. Valve: China Made Manual Valves

11. Temperature measurement and display: Digital displayer

12. Body panel: Stainless steel

13. Heat exchanger: Tubular Electric Heating Element

14. Opening method: Manual open

15. Ratio: 1:5~8

16. Container: Each dyeing container is equipped with one set of cone yarn creel

17. Accessories: Mechanical seal

Commercial offer

|

Capacity |

Model |

Cone No. |

Hank yarn Capacity |

Power of electricity heater |

Main pump power |

Dimension(L*W*H) |

|

1kg |

GR204-18 |

1*1=1 |

1kg |

0.8*2=1.6kw |

0.75kw |

/ |

|

3kg |

GR204-20 |

1*3=3 |

4kg |

2*2=4kw |

1.5kw |

0.8*0.6*1.4m |

|

5kg |

GR204-40 |

3*2=6 |

10kg |

6*3=18kw |

2.2kw |

1.1*0.8*1.5m |

|

10kg |

GR204-40 |

3*4=12 |

20kg |

6*3=18kw |

3kw |

1.1*0.8*1.85m |

|

15kg |

GR204-45 |

4*4=16 |

25kg |

8*3=24kw |

4kw |

1.3*0.95*1.9m |

|

20kg |

GR204-45 |

4*6=24 |

30kg |

8*3=24kw |

4kw |

1.3*0.95*2.2m |

|

30kg |

GR204-50 |

5*7=35 |

50kg |

10*3=30kw |

5.5kw |

1.4*1.0*2.5m |

|

50kg |

GR204-60 |

7*7=49 |

80kg |

12*3=36kw |

7.5kw |

1.5*1.1*2.65m |

Remark

1. Max diameter of cone yarn is φ160, the height is 172.

2. Voltage: Three phase 240V 50HZ

3. This dyeing machine can for cone and hank both, we will offer two different creels by request.

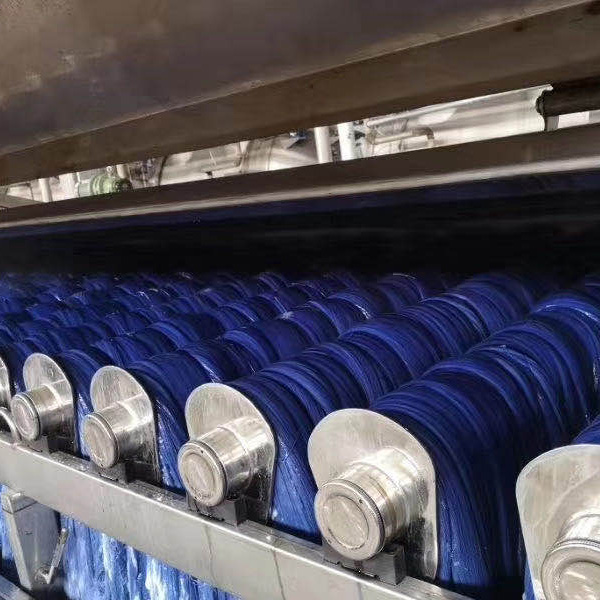

Product detail pictures:

Related Product Guide:

abide by the contract", conforms into the market requirement, joins in the market competition by its good quality also as provides a lot more comprehensive and great company for purchasers to let them turn into huge winner. The pursue from the firm, would be the clients' gratification for China Factory for Dip Dyeing Process - Electricity Built-in HTHP cone yarn dyeing machine – Singularity , The product will supply to all over the world, such as: Hungary, kazakhstan, Jamaica, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.