Bottom price Bleacjing And Oil Remove - QDY2400 washing machine – Singularity

Bottom price Bleacjing And Oil Remove - QDY2400 washing machine – Singularity Detail:

Product use range

It is mainly used in the pre-treatment of open width or cylindrical fabric. Suitable for spandex sweatcloth, cotton wool, linen gray, color strip and other fabrics.

Process

Refining, bleaching, oil removal, neutralization, deoxidation, washing, soft, and so on, there are a variety of solutions to choose from, and provide you with the equipment and process you need.

Technical Parameters:

Nominal width: 2400mm

Working form: single processing of open width cloth, double processing of cylinder cloth

Working speed: 0 ~ 60m/min

Machine power: 59Kw

Heat source: steam (0.3 ~ 0.6MPa)

Dimensions: 30000mm×4100mm×2967mm (L × W × H)

Pile temperature: 20 ~ 35℃

Energy consumption:

● Water consumption: 5 ~ 7 tons of water per ton of cloth (about 40 tons of water per ton of traditional technology)

● Electricity consumption: 59Kw per ton(traditional process electricity consumption of about 120Kw per ton)

● Steam consumption: 0.3 ~ 0.5 tons of steam per ton (traditional process steam consumption of about 3 tons of steam per ton of cloth)

Product Features

Energy saving and environmental protection, the refined fabric is uniform, no wrinkles, smooth cloth surface, soft feel, fully ensure the original characteristics of knitted fabric; Refined thoroughly, fully washed. High degree of automation, less labor, PLC+ touch screen control, safe and reliable; Grey fabric pre-treatment is not processed in the dyeing machine cylinder, dyeing machine utilization rate can be increased by more than 30%. For knitted fabric continuous pre-treatment process, solve the stacking of indentation, crease (fabric under sealed condition, temperature control at about 35 ℃), eliminates the piled up and down, inside and outside the white degree of difference and inhomogeneity, simplifies the traditional cold heap processing way too complicated operation procedures, reduce the labor intensity of workers, get rid of the unsafe factors of the process and chemicals for the operator, and break the strict requirements of the traditional process for equipment, additives, temperature, time and method. The industry has brought a new way of processing, continuous, simple, stable and safe; Save water 80%, save steam 80%, save electricity 50%, bring the enterprise great benefits.

Environmental benefits

Significant reductions in water and steam usage have resulted in significant reductions in sewage and air pollution.

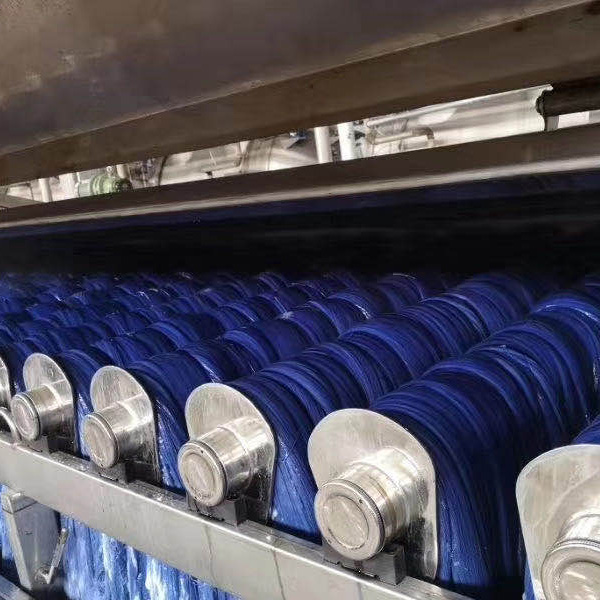

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and excellent excellent management throughout all stages of creation enables us to guarantee total buyer satisfaction for Bottom price Bleacjing And Oil Remove - QDY2400 washing machine – Singularity , The product will supply to all over the world, such as: India, Macedonia, Slovenia, We have got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.